Welcome to Our Company

Call Us :08045804881

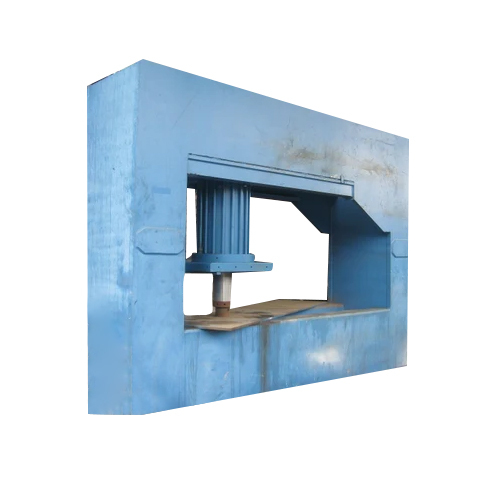

150 Ton Hydraulic Press Machine

100000.0 INR/Unit

Product Details:

- Rotation Type Vertical

- Motor Type Standard Electric / Hydraulic Motor

- Lifting Speed 8-12 mm/sec mm/s

- Control System PLC Controlled / Manual

- Features Integrated Pressure Gauge, Safety Valve

- Equipment Type Industrial Hydraulic Press

- Usage Industrial

- Click to View more

X

150 Ton Hydraulic Press Machine Price And Quantity

- 100000.0 INR/Unit

- 1 Unit

150 Ton Hydraulic Press Machine Product Specifications

- Approx. 7.5 kW Kilowatt (kW)

- Industrial

- 150 Ton Tonne

- Vertical

- Up to 600 mm (Customizable) Millimeter (mm)

- Standard Electric / Hydraulic Motor

- Integrated Pressure Gauge, Safety Valve

- PLC Controlled / Manual

- 8-12 mm/sec mm/s

- Durable, Strong, Easy To Operate

- Industrial Hydraulic Press

- Precise Pressure Control, Energy Efficient

- 380-415V Volt (v)

- Blue

- Hydraulic Press Machine

150 Ton Hydraulic Press Machine Trade Information

- 1000 Unit Per Month

- 15 Days

- All India

Product Description

150 Ton Hydraulic Press Machine that we present is ideal to be used for making good quality steel sheets in different sizes. Fabricated in a durable brass body, this machine gives optimum performance and shows excellent resistance to corrosion. It is manufactured by using superior quality raw material with the aid of state of the art technology according to the set industry standards. In addition to good functioning and precise dimensions, other attributes of this machine includes cost effectiveness and low maintenance. We are offering this range of Braided Copper Flexible Connector In Round Flat in different specifications at nominal market price.

Precision Engineering & High Capacity

This hydraulic press machine stands out with its robust construction and reliable performance. Supporting a maximum load of 150 tons and a customizable lifting height, it is suitable for critical industrial pressing operations. The precise control system ensures repeatability and accuracy for high-volume production environments.

Versatile Operation & Safety Features

With options for electric or manual operating modes and single or double acting pressing, the machine adapts effortlessly to different process requirements. Integrated safety features, including a pressure gauge and safety valve, maintain operator security, while the PLC control system simplifies operation and prevents errors.

Energy Efficient & Low Maintenance Design

The machine consumes approximately 7.5 kW of power, promoting energy efficiency for heavy industrial use. Powder coating ensures a long-lasting surface finish, and the robust hydraulic mechanism reduces downtime. Easy-to-use controls let operators achieve reliable results with minimal maintenance.

FAQs of 150 Ton Hydraulic Press Machine:

Q: How is the 150 Ton Hydraulic Press Machine operated?

A: This hydraulic press machine can be operated in electric or manual modes, with semi-automatic or fully automatic options. The control systems include PLC for automation and manual controls for flexibility, making it suitable for diverse industrial requirements.Q: What are the benefits of the 4 pillar and frame-type structures in this hydraulic press?

A: The 4 pillar and frame-type structures impart extra strength and rigidity to the machine, ensuring stable operation under heavy loads. This design allows for precise pressure distribution and enhanced safety during high-pressure industrial pressing operations.Q: When should I choose single acting versus double acting pressing operation?

A: Single acting pressing is suitable for straightforward pressing tasks, while double acting operation offers greater control for complex or multi-step processes. Selection depends on your specific application needs and the complexity of the forming or molding process.Q: Where is this hydraulic press typically used?

A: This equipment is primarily used in industrial settings such as manufacturing plants, metal fabrication facilities, and heavy engineering workshops, especially for forming, bending, and pressing large components.Q: What safety mechanisms are integrated into this hydraulic press machine?

A: The machine is equipped with safety valves and integrated pressure gauges to monitor and control operational pressures. Additionally, its PLC control system helps prevent overloading and hazardous situations, promoting a safer workplace environment.Q: How does the hydraulic press ensure precise pressure control during operation?

A: Precision pressure control is achieved through a combination of the integrated pressure gauge, PLC system, and high-quality hydraulic components, enabling consistent and accurate pressing force for various industrial applications.Q: What maintenance is required for optimal performance of the hydraulic press?

A: Regular maintenance involves checking hydraulic fluid levels, inspecting seals, cleaning the surface, and ensuring the integrity of electrical and safety systems. These tasks help prolong the machines operational life and prevent unforeseen breakdowns.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email