Coil Handling Tong

Product Details:

- Control System Manual or Electro-mechanical

- Handle Type Heavy-duty Handle

- Features Yellow Color, Industrial Usage

- Rotation Type 180/360 as per design

- Usage Industrial

- Condition New

- Product Type Coil Handling Tong

- Click to View more

Coil Handling Tong Price And Quantity

- 1 Unit

- 100000.0 INR/Unit

Coil Handling Tong Product Specifications

- Industrial

- Yellow Color, Industrial Usage

- Yellow

- 180/360 as per design

- High Quality

- New

- Up to 35 Tons or as required Tonne

- Coil Handling Tong

- Manual or Electro-mechanical

- Heavy-duty Handle

- Mechanical Lifting via Crane

Coil Handling Tong Trade Information

- Cash in Advance (CID)

- 1000 Unit Per Month

- 15 Days

- All India

Product Description

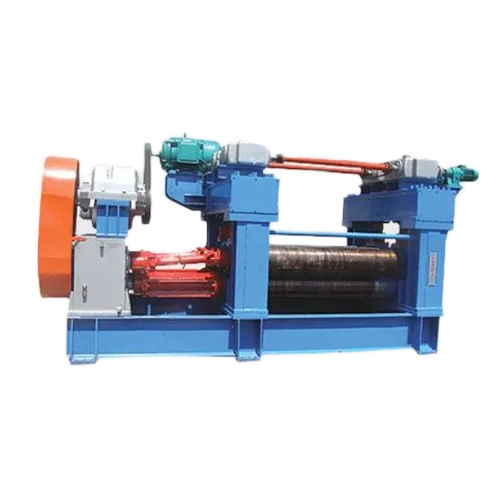

Our provided range of Coil Handling Tong widely finds its applications in the construction and material handling industries. It is well accepted in the domestic market and well received throughout the industry. Engineered with precision, this equipment is well known for its attributes such as high durability, optimum efficiency, load bearing capacity and sturdy construction. It is manufactured under the stern guidance of our deft professionals using the finest quality raw materials and sophisticated techniques in compliance with the set market quality standards. Apart from this, we provide this Coil Handling Tong in committed time frame at most reasonable rates.

Engineered for Safety and Durability

Manufactured from high-strength steel and coated with a corrosion-resistant finish, this coil handling tong ensures reliability in tough industrial settings. The mechanical lock and automatic latch serve as critical safety features during lifting operations. Its robust design supports heavy-duty use, maintaining structural integrity even with frequent handling of large coils.

Customizable and Versatile Design

Tailor your coil tong to fit specific coil dimensions or operational requirements. Thanks to customizable jaw designs and adjustable opening ranges, it is compatible with coils of varying sizes and materials. Its integration with overhead and gantry cranes provides seamless adaptation to your existing infrastructure, maximizing operational flexibility and efficiency.

Optimized for Industrial Applications

Designed for use in manufacturing, metal processing, and material handling industries, this coil tong improves productivity while reducing handling risks. Available in a striking yellow color for visibility, it supports coil rotation and heavy lifting up to 35 tons, depending on crane capabilities. Its adaptability and heavy-duty construction make it a reliable asset in any industrial workflow.

FAQs of Coil Handling Tong:

Q: How does the coil handling tong ensure coil safety during lifting and transport?

A: The tong features a specially engineered jaw design that securely grips coils while a mechanical lock or automatic latch mechanism prevents accidental release, ensuring maximum safety for both operators and materials during lifting and transport.Q: What benefits does the powder-coated or painted surface provide for this coil tong?

A: The powder-coated or painted finish provides corrosion resistance, extending the equipments operational life and maintaining its high-quality appearance even in harsh industrial conditions.Q: When should I consider using a coil handling tong with customizable opening and jaw design?

A: A customizable coil tong is ideal when you handle metal coils of different sizes, diameters (from 300 mm to 2500 mm), or special safety requirements, allowing you to tailor the tong precisely to your operational needs.Q: Where can this coil handling tong be effectively used?

A: This tong is suitable for industrial settings such as steel mills, aluminum plants, and metal processing facilitiesanywhere metal coils require safe, efficient lifting and handling with overhead or gantry cranes.Q: What is the process for operating the coil tong with an overhead crane?

A: Attach the tong to the crane hook, adjust the jaw as needed, position the tong around the coil, and activate the lifting mechanism (manual or electro-mechanical). The locking system ensures secure gripping during the entire lifting process.Q: What are the main usage advantages of this coil tong?

A: The tong offers robust steel construction, customizable features, and heavy lifting capability. Its design reduces the risk of coil damage and workplace accidents, boosting productivity and reliability in demanding industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free