Welcome to Our Company

Call Us :08045804881

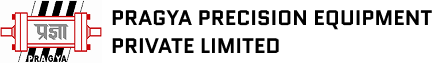

Pinch Roll Leveling Machine

100000.0 INR/Unit

Product Details:

- Usage Industrial

- Condition New

- Size Standard

- Power Source Electric

- Color Blue

- Warranty 1 Year

- Attributes Strong, Durable, Easy To Operate

- Click to View more

X

Pinch Roll Leveling Machine Price And Quantity

- 1 Unit

- 100000.0 INR/Unit

Pinch Roll Leveling Machine Product Specifications

- Standard

- Strong, Durable, Easy To Operate

- Blue

- New

- Electric

- 1 Year

- Industrial

Pinch Roll Leveling Machine Trade Information

- 1000 Unit Per Month

- 15 Days

- All India

Product Description

As a renowned company, we are engaged in manufacturing and supplying a wide range of Pinch Roll Leveling Machine. It ishighly demanded for its attributes such as reliable nature, optimum quality and efficient working.We manufacture this machine by our experts using supreme grade raw material and components, sourced from the most authentic vendors of the industry so as to ensure that it is able to stand tall on the expectations of clients. We made this available in different specifications as per the requirement of our clients. Furthermore, one can avail this range of Pinch Roll Leveling Machine at moderately prices.

Precision Leveling with Modern Design

Our Pinch Roll Leveling Machines come with polished blue surfaces, combining visual appeal and durability. Each unit delivers high-speed performance and stability, specifically designed for industrial environments demanding accuracy and consistency in sheet metal preparation.

User-Centric Control and Stable Operation

Simplified controls allow operators to adjust settings effortlessly, optimizing the flattening process for varied materials. The stable operation minimizes downtime and mechanical wear, enhancing overall productivity while maintaining safety standards within manufacturing plants.

FAQs of Pinch Roll Leveling Machine:

Q: How does the Pinch Roll Leveling Machine improve metal sheet quality?

A: By using precisely aligned pinch rolls, the machine flattens and removes unevenness from metal sheets. Its high efficiency and performance ensure consistent thickness and uniform surface, essential for downstream manufacturing processes.Q: What are the advantages of having a polished surface treatment on the machine?

A: The polishing treatment not only provides a sleek blue finish but also offers additional protection against corrosion and wear, extending the lifespan of the machine in demanding industrial settings.Q: Where is the Pinch Roll Leveling Machine typically used?

A: This machine is widely utilized in metal fabrication units, steel service centers, and manufacturing plants across India that require high-quality sheet metal leveling prior to further processing.Q: When is it beneficial to use a Pinch Roll Leveling Machine?

A: Its most beneficial during the preparation stage of metal sheets, especially when precise flatness is required for processes like stamping, cutting, or forming, helping to avoid defects and improve end-product quality.Q: What process does the Pinch Roll Leveling Machine follow to achieve stable operation?

A: The machine uses synchronized pinch rollers with simple control settings, maintaining consistent pressure and speed, ensuring stable operation throughout long production cycles.Q: How can users control and operate the Pinch Roll Leveling Machine efficiently?

A: Operators can use the intuitive control panel, which allows for easy adjustments of roller pressure and speed, ensuring optimal machine settings according to material type and thickness.Q: What benefits do customers receive by choosing your companys machine in India?

A: Customers benefit from advanced technology, reliable after-sales service, local manufacturing expertise, and customized solutions, ensuring efficiency and productivity for diverse industrial applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email