Welcome to Our Company

Call Us :08045804881

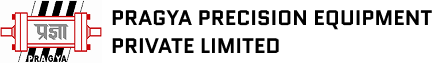

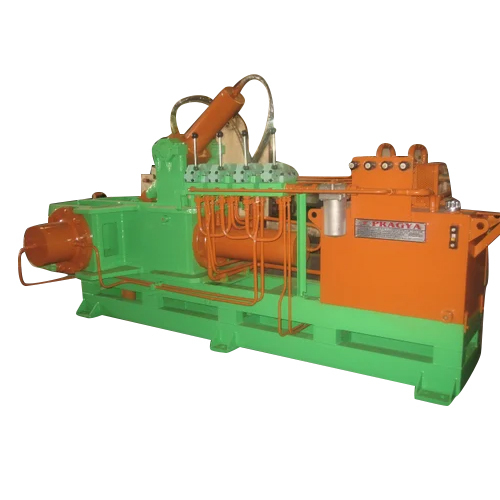

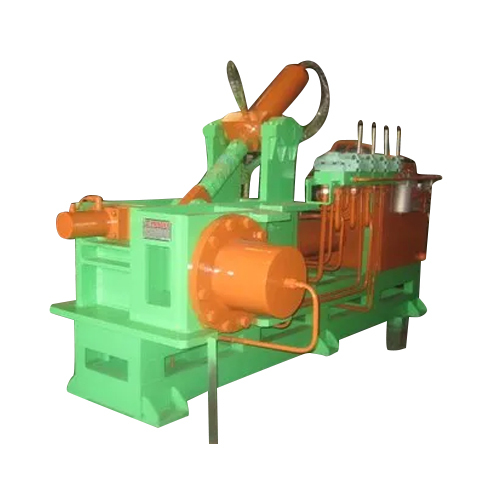

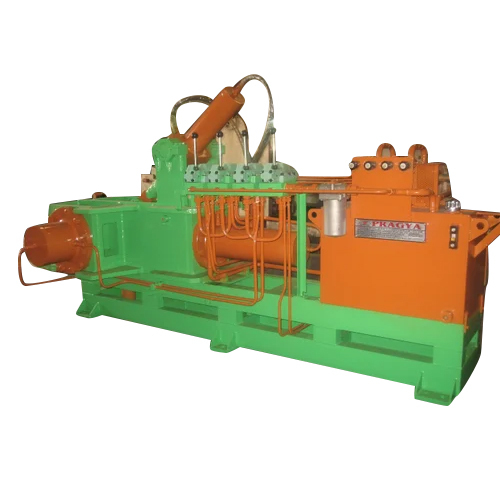

Baling Machine

500000.0 INR/Unit

Product Details:

- Features Corrosion Resistant

- Wheel Type Caster Wheels

- Rotation Type Fixed

- Handle Type Ergonomic

- Control System Automatic

- Belt Type Rubber

- Motor Type Heavy-Duty

- Click to View more

X

Baling Machine Price And Quantity

- 1 Unit

- 500000.0 INR/Unit

Baling Machine Product Specifications

- Corrosion Resistant

- New

- Caster Wheels

- Industrial

- Fixed

- Green-Orange

- Rubber

- Automatic

- Ergonomic

- User Friendly

- Baling Machine

- Electric

- Heavy-Duty

Baling Machine Trade Information

- Cash in Advance (CID)

- 1000 Unit Per Month

- 15 Days

- All India

Product Description

Baling Machine that we provide is widely used in the melting of ferrous and non-ferrous scrap and is available in different models & other specifications. It is fabricated by using finest grade components and innovative technology under the supervision of our industry engineers. It is precisely designed and is highly acclaimed in the market for its attributes such as sturdy construction, power efficiency and negligible maintenance. Further, our clients can avail this range of Baling Machine from us at economical prices.

Advanced Steel Construction for Longevity

Engineered with high-quality steel, this baling machine stands out for its remarkable durability and corrosion resistance. The sturdy frame ensures reliable performance even in demanding industrial environments. Its green-orange finish adds visibility and style, while the robust steel body maintains operational integrity over years of repeated use. This makes the machine a dependable investment for scrap management and recycling operations.

Customizable to Fit Your Operations

Every industrial setup is unique, and our baling machine offers customizable dimensions and variable bale sizes to match specific requirements. Whether your needs involve large or small scrap volumes, the equipment adapts effortlessly. The adjustable lifting speed and ergonomic controls ensure seamless operation for staff, making the process both safe and efficient across various applications.

Efficient, User-Friendly Operation

Designed for industrial use, this baler features a semi-automatic operation mode combined with an automatic control system, making complex tasks straightforward. With an approximate cycle time of 2025 seconds and low power consumption, it streamlines scrap compression processes, increases productivity, and reduces operational costsall while being easy for operators to learn and use daily.

FAQs of Baling Machine:

Q: How does the semi-automatic baling machine operate?

A: The baling machine operates through a semi-automatic system, allowing the user to load scrap materials manually while the pressing, compressing, and ejection cycles are managed automatically by the integrated control system. This setup optimizes efficiency while keeping user intervention minimal.Q: What types of materials can be compressed with this baling machine?

A: This equipment is designed specifically for compressing various types of scrap materials in industrial environments. It handles metal, plastic, paper, and other recyclable scraps effectively, streamlining waste management processes.Q: When should maintenance be performed on the baling machine?

A: Routine maintenance should be conducted as outlined in the user manual or after a specified number of operational cycles. Regular inspection of the hydraulic system, oil level in the 80L tank, and rubber belts ensures optimal performance and extends equipment lifespan.Q: Where can this baling machine be installed?

A: Designed for industrial environments, the baling machine is suitable for workshops, recycling plants, factories, and large-scale scrap yards. Its caster wheels enable easy movement within these facilities for flexible placement.Q: What is the process for customizing the dimensions and bale size?

A: Customization is straightforwardclients communicate their operational requirements to the supplier or manufacturer. The machine is then fabricated with the requested dimensions and bale sizes to fit specific scrap management needs.Q: How is the machines power consumption kept low?

A: The baler features a heavy-duty electric motor and efficient hydraulic system, both designed for optimal performance using minimal electricity. Its low power consumption helps reduce operating costs while delivering consistent results.Q: What are the key benefits of using this baling machine for scrap management?

A: Benefits include faster and more efficient scrap compression, streamlined waste handling, lower energy expenses, and reduced manual labor due to its semi-automatic controls. The corrosion-resistant body and ease of mobility also contribute to its long-term value.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email