Welcome to Our Company

Call Us :08045804881

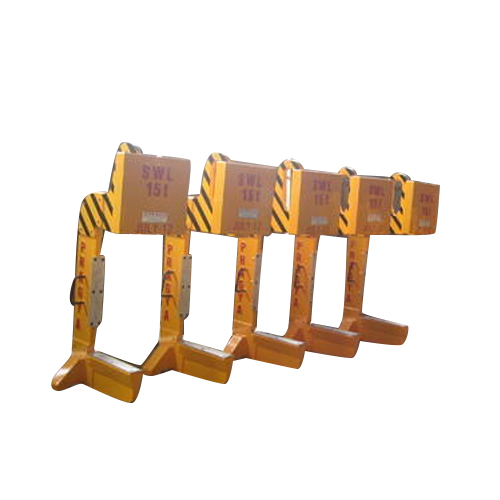

Hydraulic Sheet Leveling Machine

550000.0 INR/Unit

Product Details:

- Features Consistent leveling, Low maintenance

- Wheel Type Fixed base, No wheels

- Handle Type Standard

- Control System PLC Controlled/Manual

- Motor Type Heavy Duty Electric Motor

- Equipment Type Sheet Leveling Machine

- Usage Industrial

- Click to View more

X

Hydraulic Sheet Leveling Machine Price And Quantity

- 1 Unit

- 550000.0 INR/Unit

Hydraulic Sheet Leveling Machine Product Specifications

- Standard

- High efficiency leveling, Hydraulic operation

- Three Phase Electric Supply

- Fixed base, No wheels

- Consistent leveling, Low maintenance

- Sheet Leveling Machine

- Green

- Industrial

- 1 Year

- PLC Controlled/Manual

- New

- Standard

- Durable, Easy To Operate, Strong

- Heavy Duty Electric Motor

Hydraulic Sheet Leveling Machine Trade Information

- Cash in Advance (CID)

- 1000 Unit Per Month

- 15 Days

- All India

Product Description

Hydraulic Sheet Leveling Machine is used for straightening curling simplified sheet in cold condition and uneven sheet in cold condition and uneven sheet. It has two pinching rolls at the entrance side of the machine, they can transport the plates. It is a special equipment for mental material working. This radiator is manufactured using supreme grade raw materials and avant-garde techniques by our dexterous technocrats. Known for its best quality, clients can avail this Hydraulic Sheet Leveling Machine at industry leading prices from us.

Advanced Sheet Leveling Technology

Experience superior metal straightening with our hydraulic sheet leveling machine, designed to meet a broad range of thickness (0.512 mm) and width requirements (up to 2500 mm). The machine ensures a high-quality finish, utilizing advanced hydraulic operation and a PLC-controlled system for both precision and convenience, making it ideal for industrial-scale applications.

Robust Construction and Customization

Built with a corrosion-resistant, high-grade steel frame and equipped with alloy steel leveling rolls, this machine is engineered for durability and consistent operation. Customizable features, including roller number, lifting capacity, and leveling width, ensure that it meets specific processing needs while maintaining excellent performance and longevity.

Efficient and User-Friendly Operation

Benefit from adjustable working speeds (824 m/min) and selectable operation modes (automatic or semi-automatic) for optimal productivity. The machines intuitive control systems, powered by a heavy-duty electric motor and three-phase supply, streamline sheet leveling processes and reduce operator fatigue.

FAQs of Hydraulic Sheet Leveling Machine:

Q: How does the hydraulic sheet leveling machine work for straightening metal sheets?

A: The machine uses a set of precision-engineered leveling rolls, powered by a hydraulic operation system, to gradually correct waves and bends in metal sheets. Adjusting the rolls position and the sheets speed through the PLC or manual controls ensures smooth, consistent straightening suitable for various thicknesses and widths.Q: What is the process for operating the sheet leveling machine?

A: Operation begins by feeding the sheet metal into the machine, adjusting the settings for thickness, width, and speed as per the material and project requirements. With options for automatic or semi-automatic control, operators can manage the process efficiently, while the machines PLC system oversees accurate leveling and safety.Q: When should I use this leveling machine in my production line?

A: This machine is best used before further fabrication processes such as cutting, punching, or welding, to ensure that sheets are flat and free of distortions. Having leveled sheets improves accuracy, assembly efficiency, and quality of finished products.Q: Where can this hydraulic sheet leveling machine be installed and used?

A: It is suitable for metalworking factories, fabrication shops, and any industrial setup requiring precise sheet metal preparation. The machines robust build and customizable features make it adaptable to a variety of production environments across India and for export.Q: What are the benefits of using this machine compared to manual leveling?

A: The hydraulic sheet leveling machine offers higher efficiency, precise results, consistent output, and reduced manual labor. Its automated controls and robust construction minimize maintenance and downtime, while the corrosion-resistant finish ensures long-term productivity.Q: How is the leveling thickness and width capacity chosen for my application?

A: Selection depends on the maximum and minimum thickness and width of sheets processed in your workflow. With an operating range between 0.5 mm and 12 mm in thickness and up to 2500 mm in width (depending on the model), the machine can be tailored to fit your manufacturing requirements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free