Welcome to Our Company

Call Us :08045804881

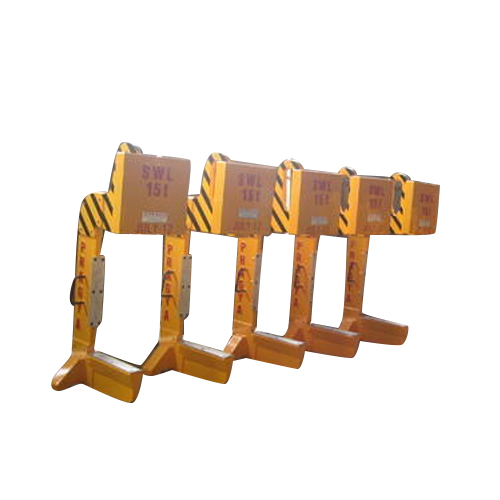

Mandrel Uncoiler Machine

500000.0 INR/Unit

Product Details:

- Wheel Type Fixed Base / No wheels

- Features Coil centering, expanding mandrel, safety interlocks

- Rotation Type 360 Rotational Mandrel

- Lifting Speed Variable, 3-20 m/min m/m

- Control System Push Button / PLC Control

- Handle Type Manual/Automatic Operation

- Motor Type Heavy Duty Electric/Hydraulic Motor

- Click to View more

X

Mandrel Uncoiler Machine Price And Quantity

- 500000.0 INR/Unit

- 1 Unit

Mandrel Uncoiler Machine Product Specifications

- Coil centering, expanding mandrel, safety interlocks

- 360 Rotational Mandrel

- 380V / 415V (Three Phase) Volt (v)

- 5000 kg Kilograms (kg)

- Fixed Base / No wheels

- Manual expansion and contraction, high load capacity

- Variable, 3-20 m/min m/m

- Up to 5 Tons (standard for Mandrel Uncoilers) Tonne

- Manual/Automatic Operation

- Push Button / PLC Control

- New

- Electric / Hydraulic

- Heavy Duty Electric/Hydraulic Motor

- Mandrel Uncoiler Machine

- 4 - 7.5 kW Kilowatt (kW)

Mandrel Uncoiler Machine Trade Information

- 1000 Unit Per Month

- 15 Days

- All India

Product Description

Mandrel Uncoiler Machine is engineered to handle solid duty gauge steel coils, shift after shift and day after day. It is highly demanded in the market for its features such as fine finish, rugged design, high durability and optimum performance. This machine is manufactured using top-notch quality components and pioneering techniques under the stern guidance of our skilled professionals. Furthermore, our precious clients can buy this range of Mandrel Uncoiler Machine from us at nominal rates.

Versatile Coil Handling Solution

The Mandrel Uncoiler Machine offers precise coil centering, manual expansion/contraction, and is adaptable to diverse coil dimensions. Its sturdy frame and customizable lifting height ensure safe and efficient handling, making it ideal for metal processing facilities seeking reliable feeding and unwinding solutions.

Safety and Efficiency Integrated

Safety is central, with emergency stop and overload protection. High load capacity, variable lifting speed (320 m/min), and a robust control system enable smooth and secure operations, reducing downtime and enhancing productivity for operators.

Powerful Hydraulic Performance

Driven by heavy-duty electric or hydraulic motors, the Mandrel Uncoiler provides high torque and consistent performance. Its standard voltage is 380V or 415V (three phase), with power consumption between 4 and 7.5 kW to suit demanding industrial tasks.

FAQs of Mandrel Uncoiler Machine:

Q: How does the Mandrel Uncoiler Machine handle different coil sizes?

A: The machine features an expandable mandrel that accommodates coil internal diameters from 450 to 530 mm and supports widths up to 1500 mm, allowing operators to work with a variety of coil dimensions for sheet metal processing.Q: What safety features are included in the Mandrel Uncoiler Machine?

A: It is equipped with an emergency stop button and overload protection, along with safety interlocks, ensuring operator and equipment safety during coil handling operations.Q: When is the Mandrel Uncoiler Machine typically used in metal processing?

A: This equipment is primarily deployed at the beginning of metal processing lines, where it feeds and unwinds sheet metal coils for subsequent operations such as cutting, stamping, or rolling.Q: Where can the Mandrel Uncoiler Machine be installed?

A: Designed for industrial environments, the machine is suitable for installation in factories and workshops handling metal processing, coil feeding, and unwinding operations. It is available from manufacturers and suppliers across India.Q: How does the operation process work for this machine?

A: Operators use push-button or PLC control systems to manage coil centering, expansion, and contraction. The hydraulic drive and high torque facilitate smooth uncoiling, while the 360 rotational mandrel provides optimal positioning.Q: What are the benefits of using a hydraulic Mandrel Uncoiler?

A: It delivers precise handling, high lifting capacity (up to 5 tons), robust construction, and custom lifting heights, streamlining coil management with reduced labor and enhanced operational efficiency.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email