Welcome to Our Company

Call Us :08045804881

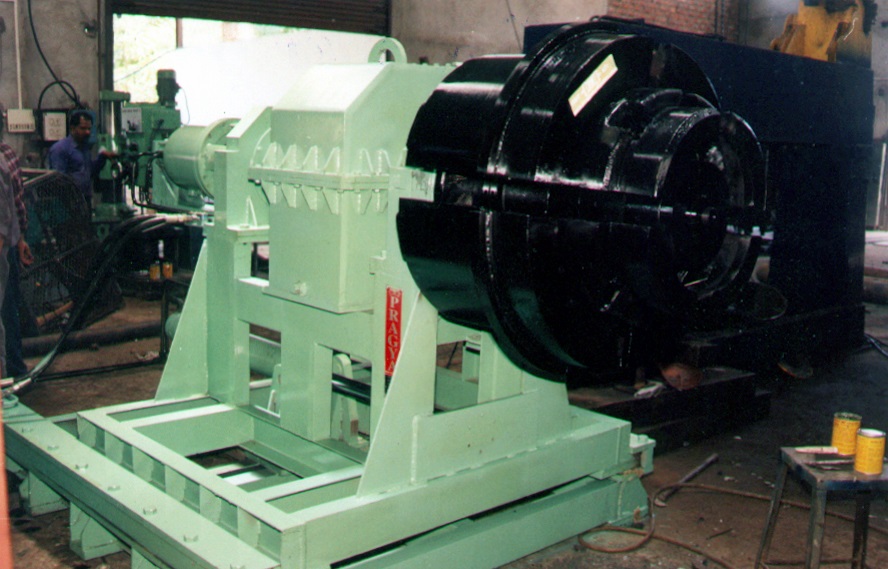

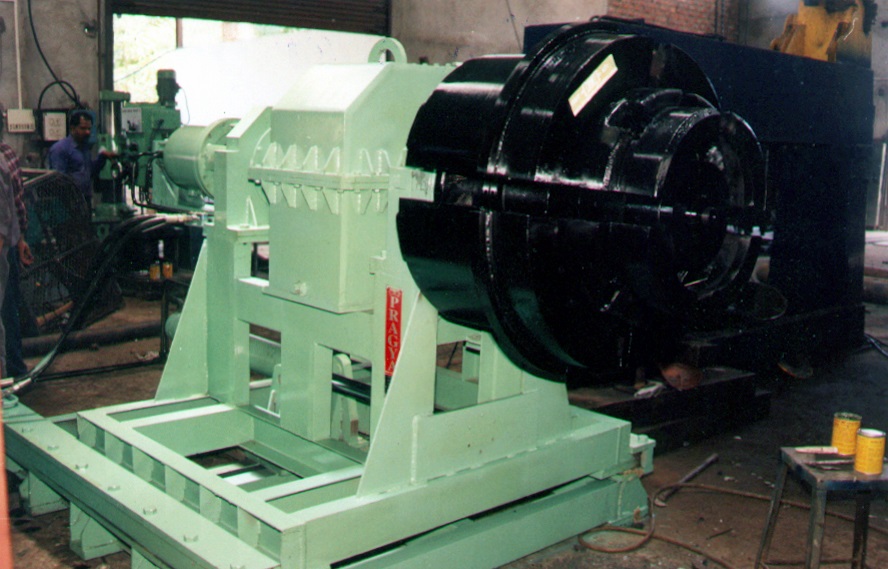

Stub Type Uncoiler Machine

500000.0 INR/Unit

Product Details:

- Features Enhanced Safety and Easy Loading

- Handle Type Automatic

- Rotation Type 360 Degree Rotation

- Motor Type Electric Motor

- Wheel Type Fixed Base (Optional Movable)

- Control System PLC Controlled

- Condition New

- Click to View more

X

Stub Type Uncoiler Machine Price And Quantity

- 1 Unit

- 500000.0 INR/Unit

Stub Type Uncoiler Machine Product Specifications

- Robust Construction, Smooth Uncoiling

- 360 Degree Rotation

- 415 V Volt (v)

- 7.5 kW Kilowatt (kW)

- Up to 10 Tons Tonne

- Electric Motor

- PLC Controlled

- Fixed Base (Optional Movable)

- Enhanced Safety and Easy Loading

- Electric

- New

- Automatic

Stub Type Uncoiler Machine Trade Information

- 1000 Unit Per Month

- 15 Days

- All India

Product Description

Stub Type Uncoiler Machine is widely used for cutting and unfolding the steel strips in various industries such as food processing and automobile In order to manufacture this machine, our professionals use advanced machines and utilize quality tested raw materials procured from the authentic vendors. It is highly appreciated by the clients for its attributes such as reliable operations, easy installation and maintenance, high efficiency, robust construction and optimum performance. In addition, our clients can avail this Stub Type Uncoiler Machine from us at most reasonable prices.

Precision Coil Uncoiling for Heavy-Duty Operations

The Stub Type Uncoiler Machine is purpose-built for demanding sheet metal handling and coil processing tasks. Its robust construction, precision engineering, and customizable features make it the preferred choice for manufacturers handling large, heavy coils. The hydraulic drive and adjustable lifting speed ensure safe and stable uncoiling, minimizing downtime and maximizing productivity.

Advanced Safety and Control Systems

Outfitted with a PLC control panel, the machine delivers user-friendly operation and enhanced safety. Its automatic and semi-automatic modes adapt to varied workflow requirements, while safety features protect both operators and equipment. The electric drive system and fixed or optional movable base provide flexibility in floor-mounted installations.

Customized for Demanding Industrial Requirements

Each machine can be tailored to suit specific lifting heights and load capacities. Designed with a precision mild steel frame, powder-coated for durability, it is suitable for continuous operation in challenging industrial environments. The system is well-suited to exporters and service providers seeking reliable coil processing solutions.

FAQs of Stub Type Uncoiler Machine:

Q: How does the Stub Type Uncoiler Machine support smooth and safe uncoiling of heavy coils?

A: The machine features a robust hydraulic drive system, adjustable lifting speed, and PLC-controlled functions, ensuring precise, smooth, and safe uncoiling up to 20 m/min, even for loads up to 10 tons. Enhanced safety systems and sturdy construction minimize coil movement and risk during operation.Q: What types of coils and materials can the machine handle?

A: It is designed for sheet metal coils with widths from 300 mm to 1600 mm, inner diameters of 450 mm to 530 mm, and outer diameters up to 1500 mm. The equipment efficiently processes mild steel and is suitable for a range of sheet metal handling and coil processing applications.Q: When should you consider using this uncoiler in your production process?

A: This machine is ideal for industries requiring reliable, high-capacity coil handling, particularly in sheet metal fabrication, automotive, and manufacturing sectors. Use it when precise, heavy-duty, and consistent uncoiling is essential for maintaining workflow and productivity.Q: Where is the Stub Type Uncoiler Machine installed, and how is it set up?

A: The machine is designed for floor-mounted installation, with customizable lifting heights and a choice of fixed or movable bases. Proper installation ensures stability and safety during operation, and our technical team can assist with setup and integration into existing processing lines.Q: What is the process for operating the uncoiler, and what control options are available?

A: Operators can utilize either automatic or semi-automatic modes, controlled by an intuitive PLC system. The electric motor and hydraulic drive enable easy loading, adjustable speed, and incremental adjustments for precise coil handling.Q: What are the key benefits of using this uncoiler machine?

A: Key benefits include enhanced productivity due to efficient uncoiling, robust and precise build for longevity, advanced safety features, and flexibility for various coil sizes. The powder-coated surface finish also offers protection against corrosion.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email