Welcome to Our Company

Call Us :08045804881

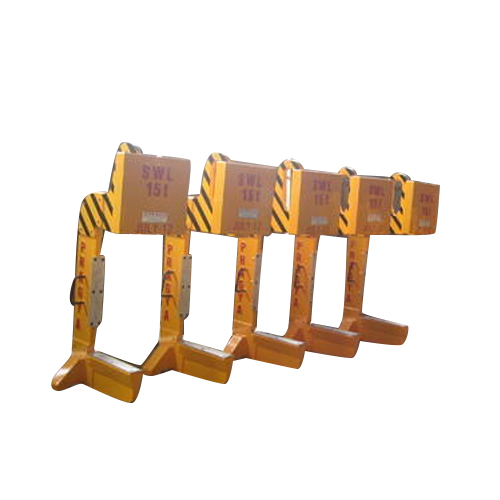

Pipe Rotator Machine

300000.0 INR/Unit

Product Details:

- Motor Type Three Phase Induction Motor

- Wheel Type PU Coated Roller Wheels

- Control System Remote Pendant / Panel

- Rotation Type 360 Degree Continuous

- Features Hydraulic Drive, Stable Performance

- Equipment Type Pipe Rotator Machine

- Condition New

- Click to View more

X

Pipe Rotator Machine Price And Quantity

- 1 Unit

- 300000.0 INR/Unit

Pipe Rotator Machine Product Specifications

- Remote Pendant / Panel

- PU Coated Roller Wheels

- Three Phase Induction Motor

- 3 KW Kilowatt (kW)

- Smooth Rotation, Adjustable Roller Distance

- 10 Tons Tonne

- Electric

- 360 Degree Continuous

- Hydraulic Drive, Stable Performance

- 415 V AC Volt (v)

- New

- Pipe Rotator Machine

Pipe Rotator Machine Trade Information

- 1000 Unit Per Month

- 15 Days

- All India

Product Description

Pipe Rotator Machine is specially designed and manufactured for purpose of meeting the requirements of enhancing productivity, increasing the extent of automatic, reducing welders working intensity and adapting to piping workshop prefabrication. The welding head will be relatively fixed, while the piping spool piece revolving at a specific rate, and the high efficient and low cost shielded welding or SAW process is adopted, so it has the features of easy-operation, reliable-performance and wide-application field. Clients can easily come to us and get this Pipe Rotator Machineat affordable market leading rates.

Versatile Pipe Handling Solution

Engineered to handle pipes of various sizes, this Pipe Rotator Machine supports diameters from 250 mm up to 3000 mm, with roller centers easily adjustable between 12002500 mm. Its powerful hydraulic drive and robust construction accommodate up to 10 tons, making it perfect for demanding industrial environments involving welding, assembly, and pipe rotation.

Enhanced Efficiency and Control

Equipped with a three-phase induction motor and electric power source (415 V AC, 3 kW), this machine delivers consistent performance while keeping power consumption low. The speed range of 1001000 mm/min and adjustable lifting height allow users to tailor the operation to specific project requirements, improving workflow efficiency and process flexibility.

Safety, Stability, and User-Friendly Operation

Operating at less than 70 dB, this machine ensures a quieter workplace. Its PU-coated roller wheels and powder-coated surface offer durability and smooth rotation, while the remote pendant or panel simplifies control and boosts operator safety. Designed for new installations, heavy-duty applications, and continuous 360-degree rotation, it delivers stable performance across various pipe handling tasks.

FAQs of Pipe Rotator Machine:

Q: How does the adjustable roller center distance benefit pipe handling?

A: The adjustable roller center distance (12002500 mm) allows the rotator to accommodate pipes of different diameters and lengths, providing stability and preventing slippage during welding, assembly, and rotation processes. This adaptability ensures that pipes from 250 mm up to 3000 mm are securely held for seamless operation.Q: What types of projects is this pipe rotator machine suitable for?

A: This machine is ideal for welding, assembly, and rotation of pipes in manufacturing plants, construction sites, and service provider workshops. Its robust build and versatile handling capabilities make it particularly useful for exporters, suppliers, and heavy-industry users in India.Q: How is the speed and rotation of pipes controlled during operation?

A: The machines speed ranges from 100 to 1000 mm/min, adjustable via the remote pendant or control panel. Its hydraulic drive system ensures smooth, stable, and continuous 360-degree rotation, allowing operators to set optimal speeds for different pipe handling tasks.Q: What is the process of setting up and adjusting this machine for different pipe sizes?

A: To set up the machine, simply adjust the roller center distance to match the pipes diameter. Roller positions and lifting height are easily modifiable, and the PLC control system makes it straightforward to fine-tune speed and rotation as needed for the specific application.Q: Where can this pipe rotator machine be installed and used?

A: It can be installed in workshops, fabrication facilities, and assembly lines, especially where large or heavy pipes need to be handledsuch as shipyards, oil and gas plants, or construction projects. Its versatile design makes it suitable for both indoor and sheltered outdoor use.Q: What are the main benefits of using a hydraulic drive with PU coated rollers?

A: The hydraulic drive provides stable, powerful rotation and lifting, while the PU coated rollers ensure smooth movement and excellent grip on pipes, reducing wear on both the rollers and the materials. This results in longer equipment life and safer operation during heavy-duty tasks.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email